Speed limiters aren’t just about slowing vehicles down. They’re about control, compliance, and—when done right—smart vehicle management. In today’s connected cars, integrating these systems with the CAN Bus isn’t a bonus. It’s the baseline.

✅Key Takeaway

CAN Bus integration gives speed limiters a serious upgrade. It connects the limiter directly to systems like the ECU, GPS, and throttle in real time.

That means sharper speed control, automatic terrain adjustments, quicker fault checks, and cleaner installs. For fleets and school buses, it’s a major safety win. This isn’t just a feature—it’s the wiring behind modern vehicle intelligence.

What Is a CAN Bus and Why It Matter

A Smarter Way for Vehicles to Communicate

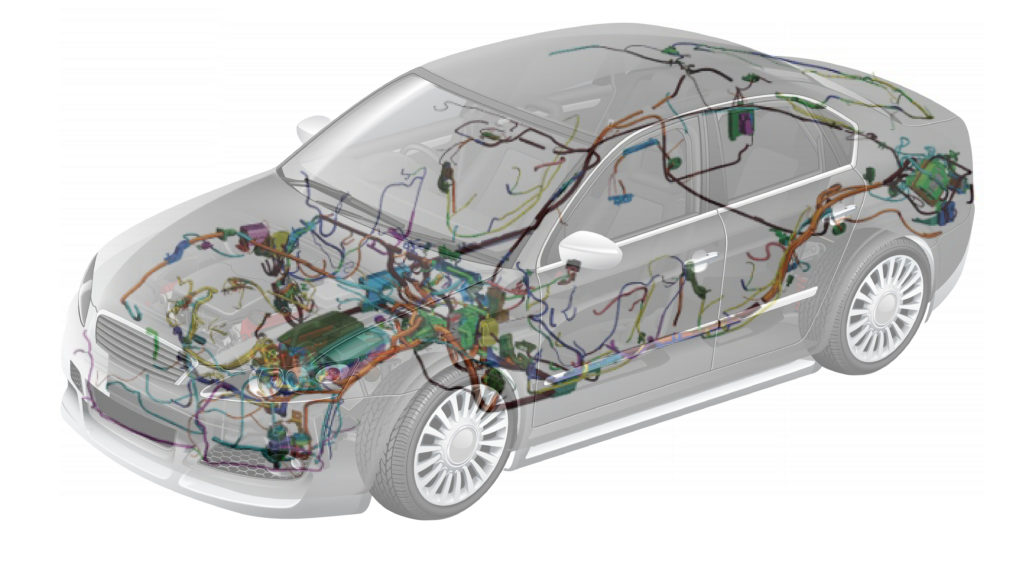

Modern vehicles aren’t just engines—they’re rolling networks. From the ECU to the ABS, every system needs to communicate. That’s where the CAN Bus steps in—it’s the wiring that keeps everything talking.

Instead of running a tangle of wires between every part, CAN Bus uses one shared line. Think of it as a group chat for your vehicle’s systems—quick, organized, and built to last.

How the CAN Bus Works

CAN Bus runs on just two twisted wires: CAN High and CAN Low. Every module—whether it’s the throttle, brakes, or transmission—can broadcast and receive signals across that single pair.

Here’s the cool part:

Each message has a CAN ID, which tells other components what kind of information it carries (speed, RPM, brake status, etc.). The other modules “listen” to the network and decide if the message applies to them. This setup reduces wiring complexity and avoids communication conflicts.

Key Benefits of CAN Bus in Vehicle Electronics

- Lightweight & Efficient Wiring – Less copper means lower manufacturing cost and better fuel efficiency.

- Real-Time Communication – Modules respond in milliseconds, perfect for safety-critical systems.

- Fault Isolation – Errors are easier to trace because the system logs them digitally.

- Compatibility – CAN is standardized, making it easier to integrate third-party modules like speed limiters.

Why It Matters for Speed Limiter Systems

Speed limiters need to know what’s happening under the hood at all times. With CAN integration, the system gains access to:

- Vehicle speed data (from wheel speed sensors)

- Engine RPM

- Throttle position

- Brake pedal activity

- Gear position

- GPS input (when available)

Real-time data lets the limiter fine-tune speed with precision. As the vehicle approaches its limit, it can ease off throttle response gradually—no jerks, no delay, just smooth control.

Smarter, Adaptive Control

Some systems, like dual-speed limiters, use CAN data along with terrain input or zone-based triggers. If a vehicle enters a school zone, the limiter instantly switches to a lower speed threshold. The driver doesn’t need to do a thing.

This is only possible when the limiter can “listen” to other systems through the CAN Bus. Without it, you’d need to install extra sensors—more complexity, higher cost, and greater risk of failure.

CAN Is the Backbone of Modern Speed Management

With CAN Bus, a speed limiter stops being just a blocker. It becomes a smart system that reads the vehicle’s signals in real time. In modern fleets, that’s not a luxury—it’s a necessity.

Whether you’re running a fleet, building safety systems, or engineering ECUs, CAN Bus is the link that makes real-time, legal speed control work.

How Speed Limiter Systems Work

A speed limiter—also known as a governor—keeps a vehicle from exceeding a set speed. It doesn’t kill the engine or hit the brakes. Instead, it trims fuel delivery or softens throttle input as the vehicle nears the limit.

These systems show up in:

- School buses (to meet safety laws)

- Fleet vehicles (to reduce fuel cost and accident rates)

- Delivery vans (to comply with local speed limits)

- Government vehicles (for regulatory purposes)

Some are static. Others, like dual-speed limiters, adjust based on conditions—terrain, GPS zones, or driving mode.

For government-regulated fleets, especially school buses and public transport vehicles, using a speed governor RTO approved system is critical to staying compliant while maintaining control and safety.

Why CAN Bus and Speed Limiters Work Better Together

Here’s where the puzzle fits: a modern limiter needs real-time data. Without CAN integration, you’re working blind. With it, the limiter reads engine RPM, vehicle speed, gear status, and brake inputs instantly.

Benefits:

- Accuracy: The system limits speed precisely—no jerking or delay.

- Adaptability: You can switch limits based on terrain or road type.

- Diagnostics: Faults are logged in the same place as engine errors.

- Clean wiring: Less clutter under the hood or dashboard.

From Data to Action: How It All Connects

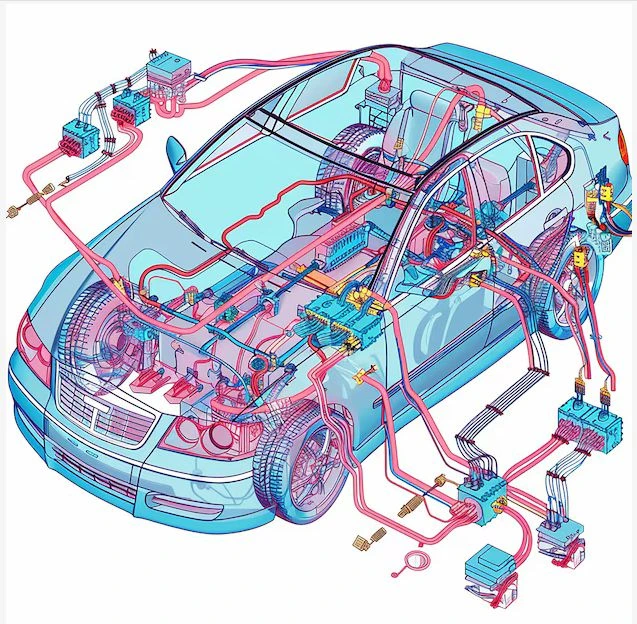

Modern speed limiter systems tap into the CAN high-speed line (usually 500 kbps). They monitor:

- Vehicle Speed Sensor (VSS)

- Throttle Position

- Brake Pedal Activation

- GPS Coordinates (if location-based limiter is used)

If a driver hits a steep hill or crosses into a city zone with lower limits, the system adapts. With dual-speed limiters, for instance, one profile kicks in on highways, another in urban zones—all without human input.

What Engineers Need to Know Before Integration

Hooking up a speed limiter to a CAN Bus might look simple—just two wires and a few signals, right? Not quite. It’s more like stepping into a tightly managed control room, where every message, ID, and timing cue has to be spot on.

Missteps—like tapping into the wrong CAN line or misreading message IDs—can cause ripple effects across the electronic control units (ECUs). From diagnostic errors to total communication breakdown, improper integration can cripple multiple vehicle systems.

1. Accurate DBC Files Are Critical

A DBC file is essentially the dictionary of a vehicle’s CAN network. It defines:

- CAN IDs (which message means what)

- Signal locations (bit start, length)

- Scaling factors (e.g., how a byte value converts to km/h)

- Message frequency

Without the correct DBC file, engineers are blind. Guessing CAN IDs or trying to reverse-engineer signals without this file can lead to serious data misinterpretation—such as reading engine RPM from a fuel temperature byte.

📌 Tip: Work with the OEM, supplier, or reverse engineering tools like Vector, SavvyCAN, or CANalyzer to extract or verify DBC accuracy.

2. Signal Shielding and Electrical Integrity

CAN Bus uses a balanced differential signal: CAN High and CAN Low push opposite voltages to cancel out noise. But even with that setup, it’s still exposed to EMI—especially in mobile or high-voltage systems.

To avoid corrupted messages or bus errors:

- Use twisted-pair shielded cables for long runs

- Ensure proper termination resistors (120Ω) at both ends of the bus

- Avoid routing CAN wires near high-voltage lines or noisy devices

📌 Note: Improper shielding can cause intermittent failures that are nearly impossible to trace.

3. Respect the Baud Rate

Most vehicles run high-speed CAN at 500 kbps, though some use 250 kbps, 1 Mbps, or mid-speed setups. Get the baud rate wrong, and the limiter won’t just stay silent—it might flood the network with junk signals and cause system faults.

Always confirm the baud rate from:

- OBD-II diagnostics

- OEM tech manuals

- DBC or CAN log analysis

Avoid devices that auto-detect baud rate unreliably. They might “see” the bus, but they won’t synchronize fast enough to participate in live communication.

4. Use OEM-Safe Protocols—No Bit Banging

“Bit banging” means manually controlling CAN messages at the software level, skipping proper CAN controllers or transceivers. This might work on test benches, but in real vehicles, it’s a bad idea.

Risks include:

- Invalid timing, which violates CAN protocol specs

- Unintended signal collisions

- Noise injection into the bus

📌 Best Practice:

Use certified transceivers, follow ISO 11898-1 and ISO 11898-2 standards, and write messages using standardized protocols like UDS, OBD-II, or manufacturer-specific CAN commands.

5. Fail-Safe Design Is Mandatory

If the limiter fails or disconnects from the CAN Bus, the vehicle should continue to operate safely without false triggers or limp modes. That’s where fail-safe protocols come in.

You’ll need to:

- Monitor CAN heartbeat signals

- Set fallback speed logic in the limiter firmware

- Ensure it doesn’t freeze throttle commands or spam the bus

📌 Compliance Note:

In regulated environments (e.g., EU transport safety laws), fail-safe behavior may be legally required for aftermarket modules.

In Summary

Integrating a speed limiter with CAN Bus is a technical task that demands precision. Engineers must know the structure, shielding, timing, and protocol standards of the CAN environment they’re entering. A successful integration isn’t just about controlling speed—it’s about doing it without interfering with the vehicle’s broader nervous system.

Meeting Road Safety Standards Through Smarter Systems

Many countries now mandate CAN-enabled limiters for commercial vehicles. These systems often need:

- Speed lock thresholds

- Tamper-proof configurations

- Remote override or diagnostic support

Resolute Dynamics, for example, includes CAN diagnostics in its School Bus Safety Systems and Dual-Speed Limiter offerings—ensuring both compliance and smooth control.

Handling Older Vehicles Without CAN Support

What if the vehicle doesn’t support CAN? Retrofitting is still possible using analog-to-digital conversion modules, though accuracy dips. These conversions often rely on:

- RPM pickups

- OBD-II piggyback devices

- External GPS modules

Not ideal—but workable when you’re stuck with legacy fleets.

What the Future Holds for Speed Limiter Systems

The next wave? Expect more from telematics and V2X (Vehicle-to-Everything) communication. Soon, speed limiters may react to:

- Live traffic feeds

- Weather conditions

- Pedestrian presence alerts

Artificial intelligence may also come into play, learning driver patterns and adjusting speed limits accordingly—not just reacting, but predicting.

Final Thoughts

Marrying speed limiters to the CAN Bus transforms a passive safety system into an intelligent control hub. It’s not just about stopping drivers from speeding—it’s about smarter decisions, fewer accidents, and a tighter grip on compliance.

If you’re building or managing a fleet or developing aftermarket systems, CAN Bus integration isn’t just the better option. It’s the only one that keeps you competitive—and legal.