Short Answer:

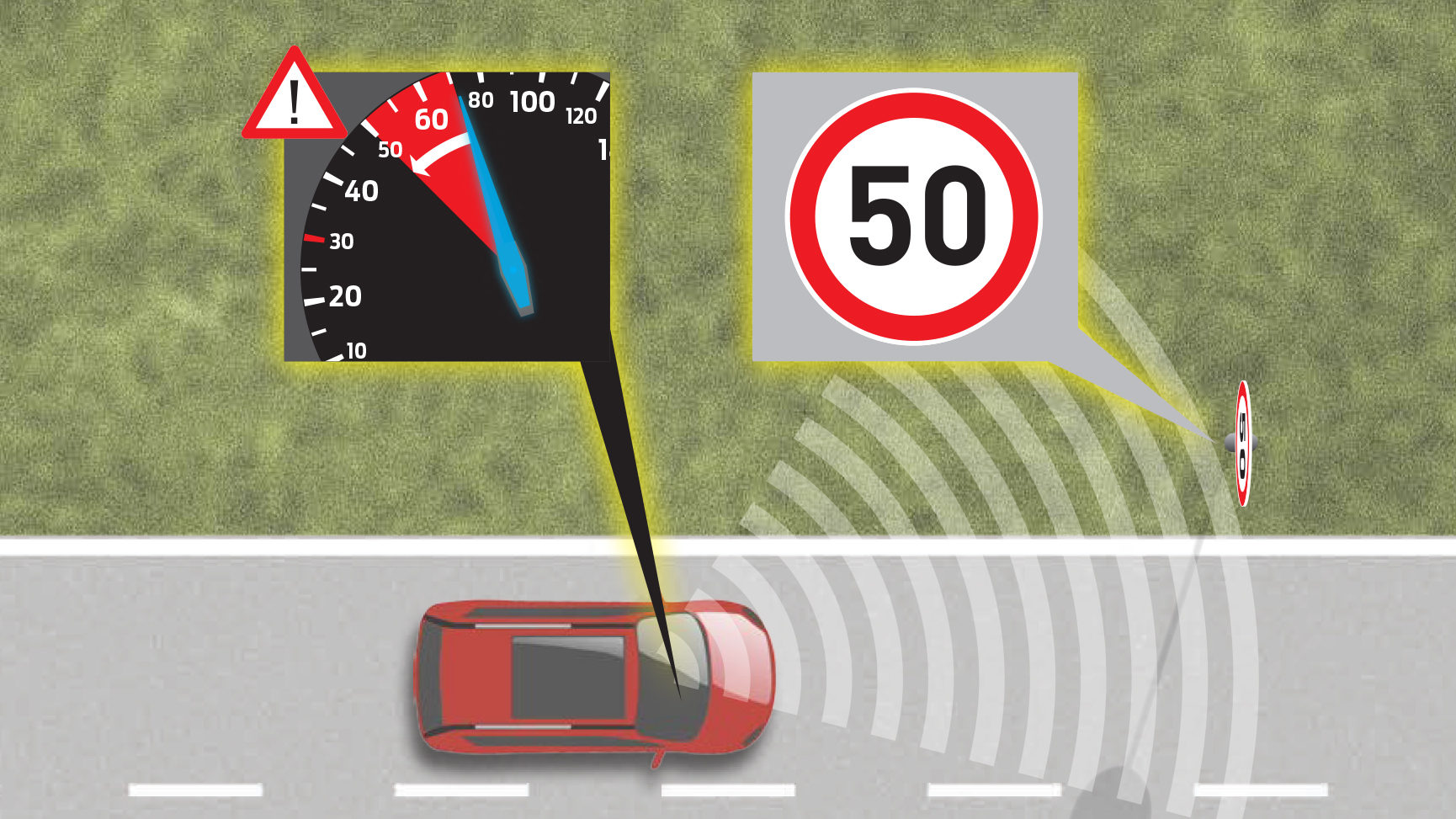

Speed limiter calibration is really just making sure the limiter and the car’s brain—the ECU—are on the same page about your actual speed. It works alongside sensors and GPS so the number you set is the speed you actually get on the road.

It’s done to recognised standards like ISO 17025, SAE J2263, or India’s IS 11827:2008. When it’s spot-on, you’re legal, safer, and maybe even saving a little on fuel.

Why Speed Limiter Calibration Matters

Speeding is still one of the biggest reasons people end up in crashes. You’d think throwing a speed limiter on a vehicle solves that—but not always.

Here’s the thing: if the limiter’s calibration is even a little off, it might cut in too early, or worse, too late. That small difference can mean a ticket, a close call, or something far worse.

Understanding Speed Limiters and How They Work

Not all speed limiters are built the same.

-

Electronic ones talk directly to the ECU (that’s basically the car’s brain) and limit how much fuel or air the engine gets.

-

Mechanical types—you’ll still find them in some older trucks—physically stop the throttle from going past a set point.

-

GPS-based limiters change the cap depending on where you are, which is handy when switching between city streets and open highways.

To ensure accurate and regulation-compliant performance, every speed limitation device must be properly calibrated to reflect real-world driving conditions.

The ECU’s basically the boss—it calls the shots and the engine listens. But if it’s not on the same page as the limiter, your speed control starts to wander, and that’s when trouble creeps in.

What Is Speed Limiter Calibration?

Think of calibration like tuning a guitar—one string’s off, and the whole song sounds wrong. In a vehicle, it’s about getting the limiter lined up with the engine’s data, the sensors, and the GPS so they’re all singing the same tune.

The process usually involves:

-

Pulling live data from the ECU

-

Checking speed thresholds with a diagnostic scanner

-

Adjusting the programmed limit if necessary

-

Confirming accuracy through a road test or simulation

The goal is simple: make sure the limiter’s reading matches the vehicle’s actual speed.

Top Calibration Tools Used in the Industry

Calibrating a speed limiter takes more than plugging in a gadget and pushing buttons. It calls for precision tools that can communicate directly with a vehicle’s electronic systems—especially the Engine Control Unit (ECU). These tools read speed data, adjust parameters, and verify that all settings meet mechanical and legal thresholds.

1. OBD-II Diagnostic Scanner

An OBD-II scanner is the most common starting point. It connects to the OBD-II port under the dashboard to read fault codes, limiter settings, and sensor data from the ECU.

Role in calibration:

-

Displays current limiter parameters

-

Allows reset or adjustment of those parameters

-

Confirms limiter function through real-time feedback

Examples: Autel MaxiCOM MK808, Launch X431 Pro V+, Bosch KTS series

Some advanced scanners offer bi-directional control—sending test commands to throttle or fuel systems to confirm limiter response.

2. ECU Programming and Reflashing Tools

When deeper adjustments are required, ECU programming tools rewrite the firmware where speed limiter logic is stored.

Why it’s critical: If firmware data is wrong or corrupted, the limiter can fail entirely. Programming tools restore accurate, regulation-compliant logic.

Functions:

-

Full ECU mapping and cloning

-

Adjusting max speed, throttle response, or RPM limits

-

Managing firmware versions for compatibility

Examples: KESSv2 (Alientech), CMDFlash, Dimsport Genius

These tools demand skill—errors can disable the ECU entirely. Many come with OEM-specific protocols to avoid compatibility issues.

3. GPS Calibration Devices

GPS-based limiters need tools that sync vehicle speed data with satellite location data.

What they handle:

-

Zone-specific speed caps (e.g., school zones, highways)

-

Calibration to ensure real-time speed/location accuracy

-

Prevention of early or late limiter activation

Examples: VBOX Vehicle Test Suite (Racelogic), Teletrac Navman IQ Tools, Q-Free Intrada GPS Limiters

Typical kits include GPS simulators, dual-system diagnostics (ECU vs. GPS), and geo-fencing test software.

4. Handheld Multi-System Diagnostic Tools

These portable devices check the full sensor network that affects limiter accuracy.

Checks include:

-

Wheel speed sensors

-

Throttle position sensors

-

Brake switch sensors

-

Fuel injection timing

Key features:

-

Real-time sensor graphs

-

Full system health scans

-

Data logging for compliance records

Examples: Foxwell GT60, Thinkcar ThinkTool Master, Snap-On Solus Edge

Ideal for multi-axle trucks, buses, and specialized vehicles.

5. Mobile Calibration Kits for Fleet Operations

Mobile kits let technicians recalibrate vehicles on-site, reducing downtime.

Benefits:

-

On-the-spot adjustments after repairs or installations

-

Wireless or Bluetooth ECU connections

-

Fleet software integration for automatic scheduling

Examples: Jaltest Multibrand Fleet Diagnostics, Texa Navigator TXTs, Hino Insight Remote Calibration Tools

These kits are often ruggedized for field use and work with multiple vehicle brands.

Recommended Calibration Frequency

Calibration intervals depend on vehicle use, environment, and regulations, but common benchmarks include:

-

Annually – Standard for most commercial fleets worldwide

-

Every 20,000–30,000 km – For high-mileage vehicles such as school buses and freight trucks

-

Post-repair – After work on the ECU, throttle body, or GPS module

-

Following software updates – Any change to the vehicle’s control systems can affect limiter accuracy

Some countries, including India and the UAE, require proof of annual calibration by law. Always verify requirements with local transport authorities.

International Calibration Standards

Speed limiter calibration is no place for guesswork. Global and regional standards set the technical and legal foundation, ensuring consistent accuracy across tools, methods, and personnel. Skipping compliance can lead to penalties, grounded fleets, or liability in the event of an accident.

1. IS 11827:2008 – India’s Standard for Speed Governors

Covers both mechanical and electronic systems, defining:

-

Design and performance requirements

-

Maximum set speeds by vehicle category

-

Acceptable error margins (often ±2 km/h)

-

Testing protocols, from bench trials to road testing

-

Durability expectations under heat, vibration, and dust

Paired with AIS-018, this standard applies to commercial vehicles in India. Calibration must be carried out by agencies or technicians authorized by the Automotive Research Association of India (ARAI).

2. ISO/IEC 17025 – Requirements for Testing and Calibration Labs

Sets global benchmarks for lab competence, measurement accuracy, and traceability. It covers:

-

Calibration intervals and environmental conditions

-

Use of standard reference materials

-

Documentation protocols for each calibration job

-

Verification of repeatability and reproducibility

-

Internal and external audits

Labs must link results to recognized bodies such as NIST (USA), NABL (India), UKAS (UK), or DAkkS (Germany). Using an accredited lab ensures results are accurate, defensible, and internationally recognized.

3. SAE J2263 – Speed Control Systems in On-Road Vehicles

Defines requirements for throttle and brake interfaces, control logic, emergency overrides, diagnostic compatibility, and post-calibration data storage. Widely used in North America, it aligns with U.S. Department of Transportation and FMCSA expectations, making it valuable for cross-border fleets.

4. ASTM E2658 – Speed Verification in Test Machines

Not written specifically for vehicles, but relevant to labs using simulation rigs. Covers:

-

Methods for verifying speed accuracy in machines

-

Use of calibrated sensors and reference meters

-

Documentation and benchmark comparison procedures

Often used alongside ISO/IEC 17025, it adds extra procedural rigor for R&D and validation work.

The Role of Traceability: NIST, NABL & Beyond

Traceability is a legal requirement in speed limiter calibration. Every tool, reading, and adjustment must connect directly to a recognized national or international measurement standard.

Key accreditation bodies include:

-

NIST (USA): Defines reference units such as meters and seconds used worldwide

-

NABL (India): Accredits calibration labs under ISO/IEC 17025

-

UKAS (UK) and DAkkS (Germany): European authorities aligning with ISO standards

-

CNAS (China): Maintains compatibility between local and global calibration norms

In practice:

When a lab claims its tools are certified, it should be able to show a documented chain linking its results back to these bodies—no missing steps, no vague assurances.

Common Calibration Errors & How to Avoid Them

Even a well-done calibration can fail if certain issues creep in:

-

GPS drift: Satellite-based systems can misread speed in tunnels, dense cities, or areas with poor reception.

-

Sensor faults: Dirty or damaged wheel speed sensors feed false data into the system.

-

Wrong ECU mapping: Installing an incorrect software patch can disable the limiter entirely.

-

Calibration drift: Over time, even accurate settings can slowly shift out of spec.

Prevention: Test regularly, maintain sensors and wiring, and work only with certified tools and accredited technicians.

Fleet-Level Calibration: Scaling the Process

Manually calibrating dozens or hundreds of vehicles wastes time and resources. Large fleets benefit from systems that centralize and automate the work.

Key solutions:

-

Bulk calibration tools: Connect to multiple ECUs through a central server.

-

Telematics integration: Schedule and track calibration from a dashboard.

-

Digital calibration logs: Maintain vehicle-specific records for audits and insurance.

Some setups use APIs to pull mileage or diagnostic alerts directly from vehicles, triggering recalibration automatically.

The Future of Calibration: AI, Automation & Cloud Tools

Calibration is moving toward intelligent, always-connected systems.

Emerging trends:

-

Predictive calibration: AI forecasts when a limiter is drifting out of spec.

-

Cloud-linked diagnostics: Vehicles upload calibration data for real-time analysis.

-

Self-calibrating systems: Autonomous and advanced vehicles adjust their own limiters using live driving data.

These advances cut human error and keep speed control precise without constant manual intervention.

Final Thoughts: Why This All Matters

For fleets, schools, or individual operators, speed limiter calibration isn’t optional—it’s a safeguard. Done right, it keeps vehicles safe, legal, and performing at their best. Skipped or sloppy calibration can mean fines, crashes, and costly downtime.

With the right tools, adherence to recognized standards, and a strict schedule, calibration becomes more than compliance—it’s active risk prevention. It protects lives, optimizes operations, and keeps you ahead of regulators.

If you need certified tools or expert calibration support, contact Resolute Dynamics. Safety shouldn’t slow you down.