A leading logistics company in Singapore cut road accidents by 40% within a year. Their approach blended speed limiters to keep vehicles in check, telematics for live fleet insights, and driver behavior analytics to pinpoint risky habits.

Safety metrics became their compass, regulatory rules their guardrails, and targeted training their tool for change. The results spoke for themselves: lives spared, smoother operations, and lower insurance bills. Here’s the playbook they followed — and how others can put it into action.

Safety Wasn’t Optional Anymore

Fleet safety isn’t just about ticking boxes. When trucks are constantly on the road, the margin for error is razor thin. This logistics company knew that rising accident rates weren’t just hurting their bottom line—they were risking lives and licenses.

They needed a change—not just new hardware, but a complete shift in how safety was managed across their commercial vehicle fleet.

That’s when they turned to advanced technologies like the Singapore speed limiter device, backed by GPS tracking and smart telematics systems, to gain real-time insights and enforce better control over driver behavior and vehicle performance.

Background of the Logistics Firm

Fleet Composition & Operational Routes

The company’s fleet includes:

-

Heavy goods vehicles (HGVs) for long-haul industrial cargo

-

Medium-duty trucks for urban deliveries

-

Refrigerated trucks for temperature-sensitive goods

-

A handful of light commercial vans used for last-mile operations

Challenges Before Safety Tech Integration

Prior to adopting any speed management or telematics systems, the company’s safety profile was troubling:

-

An average of 20+ road incidents per year

-

A rise in rear-end collisions, especially in congested zones

-

Several near-miss reports filed by drivers and third-party witnesses

-

Fuel inefficiency tied to erratic acceleration and over-speeding

-

Growing insurance premiums due to accident history

-

Customer complaints tied to delays caused by vehicle breakdowns or investigations

Some of the firm’s larger vehicles were involved in multi-vehicle pile-ups due to overspeeding in expressway zones where stopping distances are longer. Internally, fleet managers struggled with accountability, as there was no visibility into what drivers were doing once they left the depot.

Internal Pressure Points

-

Driver morale was low, especially after disciplinary actions following incidents

-

Managers had limited tools for proactive enforcement—they could only react after something happened

-

Vehicle downtime increased due to body repairs and investigations

-

Regulatory scrutiny from the Land Transport Authority (LTA) intensified, particularly with new digital safety audit standards on the horizon

This mix of operational risk, compliance pressure, and brand reputation concerns pushed leadership to act.

They realized that a tech-driven, policy-enforced safety initiative wasn’t optional—it was a strategic necessity. That’s when they began evaluating speed limiter systems, GPS tracking, and behavioral telematics as part of a broader fleet risk reduction strategy.

The Road Safety Challenge

Fleet managers started by digging into the root causes of the accidents. Speeding stood out immediately. Most crashes were happening during peak hours or on long-haul deliveries.

Their existing monitoring system was outdated. There was no way to control how fast the drivers were actually going in real time.

Add to that the pressure of tight schedules and a lack of on-road accountability, and the result was predictable: overspeeding, erratic braking, and fatigue.

On top of this, they were facing compliance pressure from the Land Transport Authority (LTA), which had recently introduced stricter safety enforcement on commercial fleets.

Implementing the Speed Limiter Solution

Choosing the Right Speed Limiter Technology

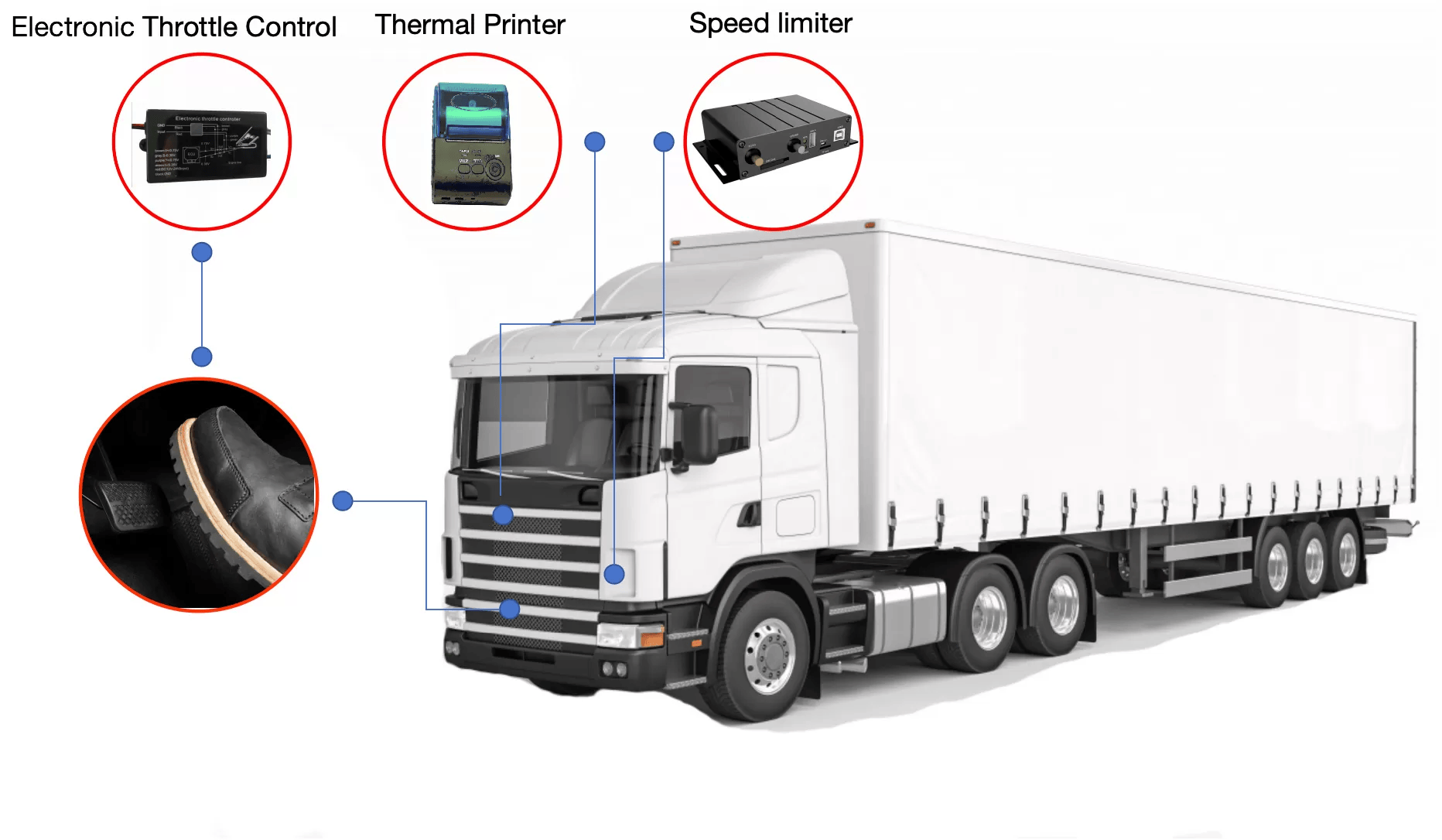

After an internal audit of available technologies, the fleet managers chose a dual-layered solution:

-

ECU-integrated speed limiters — These electronically restrict the vehicle’s top speed by cutting fuel input when the set threshold is reached.

-

GPS-linked dynamic limiters — These use real-time location data to automatically adjust speed limits based on road type and legal zones.

This was a big leap forward from older mechanical governors, which offered no flexibility or real-time monitoring. The new system offered intelligent speed adaptation (ISA), an advanced feature aligned with European Union transport safety standards and gaining popularity in regulated markets like Singapore.

Step-by-Step Rollout Process

The implementation process was carried out in phases to avoid disrupting operations:

Phase 1: Audit and Custom Configuration

-

Fleet routes were analyzed to identify urban, suburban, and expressway segments

-

Speed zones were mapped using GIS-based data, allowing geo-fencing by road type

-

Configurations were made per vehicle class (light, medium, and heavy commercial)

Phase 2: Hardware Installation

-

Over 300 vehicles were retrofitted within six weeks

-

Installations were done during night shifts or off-duty windows to avoid downtime

-

All devices included tamper-detection features, alerting managers if interference was attempted

Phase 3: Geo-Zoning and Smart Speed Adaptation

-

Urban zones were limited to 70 km/h max

-

Expressway zones were capped at 90 km/h

-

In school zones and high-risk areas, some vehicles had a custom limit of 50 km/h, auto-triggered by GPS

-

The GPS system dynamically updated vehicle speed limits based on location, time of day, and road classification

In-Cab Driver Alerts and Feedback

To help drivers adjust without confusion or stress, driver assistance systems were installed alongside the speed limiters.

These included:

-

Visual alerts on the dashboard when approaching the speed cap

-

Audible beeps if the speed threshold was about to be exceeded

-

An integrated driver coaching module that gave feedback post-trip based on compliance

This not only improved adherence but reduced frustration, especially among senior drivers who were initially skeptical.

LTA-Compliant and Audit-Ready

All speed limiter devices were Land Transport Authority (LTA)-certified, meeting strict Singapore regulatory standards for commercial fleet equipment. Compliance was a critical component of the program.

Here’s how it was ensured:

-

Devices logged speed data continuously, with timestamps and GPS coordinates

-

Logs were stored securely in the cloud and available on-demand for LTA audits

-

Each installation was issued an LTA-accepted certificate of compliance

-

Devices passed ISO 15622 and SAE J2264 standards for speed governance systems

Post-Implementation Monitoring

Once the system was live, fleet managers began to see immediate behavioral shifts:

-

Drivers reduced speeding incidents by over 65% in the first quarter

-

Average trip times stabilized, with fewer route deviations

-

Insurance providers took note of the proactive risk controls and began discussing premium adjustments

Perhaps most importantly, driver confidence began to grow. Many felt safer behind the wheel knowing the vehicle itself helped enforce good habits. It wasn’t a restriction—it became a form of protection.

Complementary Technologies That Made It Work

Speed limiters alone don’t drive change. The firm went one step further by combining them with a telematics system that offered real-time visibility and control.

The setup included:

-

GPS tracking with route heat maps

-

Driver behavior analytics for scoring and feedback

-

Fleet management software to schedule maintenance and track downtime

-

Alerts for idling, hard braking, sudden lane changes, and aggressive driving

This data helped management spot patterns: drivers who consistently pushed limits, routes with frequent violations, and even vehicles that needed servicing.

Meeting Safety Compliance and LTA Regulations

Singapore’s transport ecosystem is highly regulated. To avoid fines and retain their operating license, the logistics firm had to stay ahead of LTA’s commercial vehicle rules.

Their new system ensured:

-

Automatic logging of driver hours (for fatigue compliance)

-

Monthly speed reports submitted for audit

-

Digital speed limiter certificates available for inspections

-

Full adherence to ISO standards for fleet safety

Driver Training and Engagement

No safety system works without the people behind the wheel buying into it.

The company launched an internal Driver Safety Training Program. Here’s what worked:

-

Real-time coaching through in-cab alerts

-

Monthly feedback sessions using driver scorecards

-

Performance-based incentives for safe driving

-

Public recognition of top safety performers

Instead of making it about punishment, they made safety a source of pride. Slowly but surely, driving habits began to shift.

Key Results Achieved

Within the first year of implementation, the results spoke for themselves:

-

40% reduction in road accidents

-

Fuel efficiency improved by 12%

-

Maintenance-related downtime dropped by 25%

-

Insurance premiums were renegotiated and lowered

-

Driver satisfaction scores improved in internal surveys

Most importantly, the firm received zero traffic penalties related to speeding that year.

ROI and Operational Impact

Initially, the investment in hardware, software, and training seemed high. But by the end of year one, the Return on Investment (ROI) was undeniable.

-

Total cost of implementation: ~$200,000

-

Estimated yearly savings:

-

$60,000 from fuel reduction

-

$80,000 from lower accident-related costs

-

$30,000 saved on insurance premiums

-

-

Break-even point: Month 9

The company also reported increased delivery punctuality, thanks to fewer disruptions and better route planning.

Lessons Learned and Best Practices

Here’s what the team learned during this transformation:

-

Speed governance works best when it’s invisible—don’t rely on manual intervention.

-

Data wins arguments. Sharing driver scores and incident heatmaps made conversations factual, not emotional.

-

Start with leadership. Change must be led from the top. The GM publicly committed to safety KPIs.

-

Reward, don’t punish. Positive behavior reinforcement created momentum faster than fines or threats.

What This Means for Other Fleet Operators

If you’re running a logistics or commercial vehicle fleet in Singapore—or anywhere with strict transport laws—this case shows what’s possible.

Speed limiters, when combined with driver data and fleet policy enforcement, become more than a tool. They become a culture.

With LTA tightening its grip on non-compliant fleets and safety standards rising, proactive firms will always stay ahead of the curve.

Conclusion

Reducing accidents isn’t rocket science. It’s about control, data, and culture. This logistics firm proved that technology can drive behavior, not just monitor it. And in a place like Singapore, where safety regulations are strict and the roads are busy, that’s not just smart—it’s survival.

If you’re still relying on traditional fleet management, it’s time to think bigger. Think safer. Think smarter.